Do I really need a cool room, or can I just use some fridges and freezers? If you’ve setup a kitchen or you’re looking to do so soon, chances are you’ve asked yourself this question at one point or another, when considering the most appropriate cooling options for your business.

Determining whether you’ll need a Cold Room or Fridge can be difficult, so we’ve done our best to highlight the key points of difference between the two, so you can make a better informed decision.

Space

First and foremost, it’s important to consider the room you have in your fitout and the adequate space you will need for cooling (now and in the near future).

For example, a 2-door upright kitchen fridge will net you between 800-1000L of storage capacity, and a 2-meter long chest freezer in the 600-700L vicinity. Both cold rooms and fridges feature adjustable shelving so you can fit more smaller boxes, or less shelves for bigger ones. So for this exercise we need to consider volume, being the sheer amount of space you can fill up with stock.

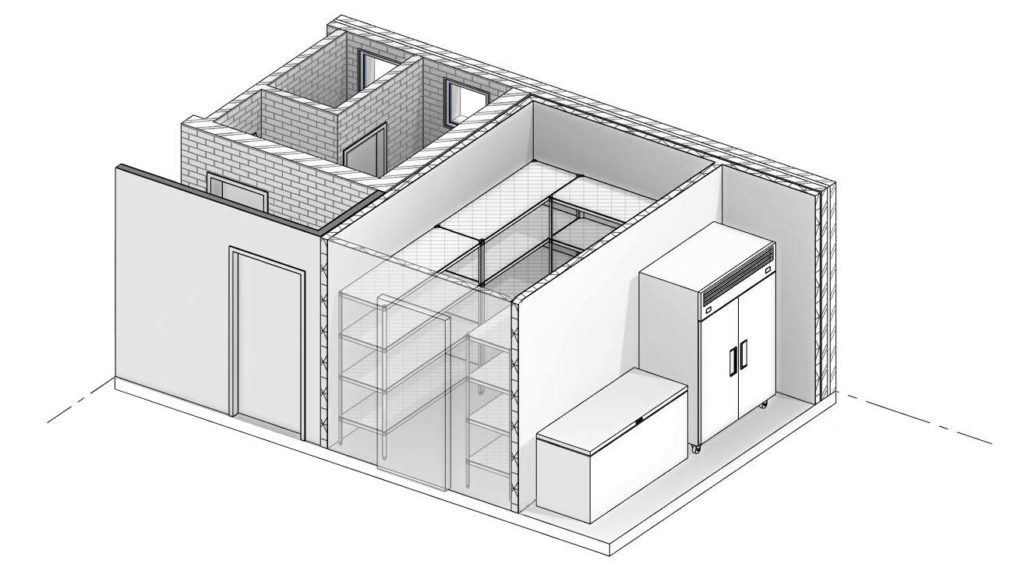

Using roughly a 3 meter by 2 meter cold room, while allowing space around your shelving for coving, would net you with approximately 6.7 lineal meters of shelving. Considering a 2m usable height from the bottom shelf to the top of your top box, and running 600mm deep shelves, this would equate to 7920 liters of available storage.

Compared with available products, this is the equivalent of over nine two-door upright cabinets, or almost twelve two-meter chest freezers. If chest freezers were the chosen equipment, they would take up nearly 60% more floor space than aforementioned cold room, while only providing two thirds of the storage.

It is also important to note that the advertised literage for cabinets and fridges is not entirely usable due to the internal space needed for air circulation around the food, making these volume estimates hard to define.

Price

As with anything in business we’ve all heard you should aim to equip yourself the best you can afford, in a bid to reduce your operational costs. Understandably, price is often a key factor for businesses in their cooling selection.

The cost for building a cold room varies between $15-$20k depending on design specifics. For comparison, this would be relative to the cost of 4-5 commercial quality upright fridges, or over 9 chest freezers. It would cost you an extra 5 upright refrigeration cabinets, just to get the same amount of volume as a cold room can hold.

Usage and Frequency

Put simply, in small to medium sized kitchens and food service establishments, cold and freezer rooms are designed for bulk storage and fridge/freezer cabinets are designed for service usage.

A big consideration to make is how frequently you’ll use your cold rooms. It does not make sense to have hundreds of cold room door openings per day. Neither does it to try to rotate carton-sized stock through refrigerator shelves.

The labour of working bulk stock out of multiple cabinets and chest freezers becomes costly and confusing and requires strict attention from all employees to ensure food safety is prioritised, while also posing potential lower back strain and other physical issues.

Implementing the First in First Out (FIFO) method much easier with a cold room, rotating food into day use/service period cabinets.

The time taken between delivery and storing goods at temperature is also significantly increased due to handling in fridges, many commercial fridges and freezer cabinets having door opening sizes and center mullions between the doors make handling larger delivery stock awkward.

Fridges and freezers do offer minimal cold-air loss when retrieving food. If you were to opt for a cold room, this issue can be resolved by having a dedicated storage fridge for items that require regular access, reducing the need to open cold rooms as frequently and therefore reducing the thermal load.

Running Costs

Whether you choose a fridge or cold room for your business, the overall lifetime costs of running the cold room in comparison to multiple fridges, should be a key consideration for your operating expenses. A single cold room motor running quickly becomes far cheaper than multiple fridge motors.

A commonly missed factor is also the heat rejection within the work space. A cold room with a remotely located compressor/condenser unit removes the motor heat from the work environment. Multiple fridge motors running in a tight kitchen area add considerable heat and require additional ventilation/extraction.

Counter balancing a hot kitchen with air-conditioning compounds your running costs, and worse – once closed up at night fridges have a high chance of breakdown failure if they overheat in an unventilated room – resulting in high amounts of food-wastage.

Planning Ahead

Given that the menu requirements directly affect the overall refrigeration and storage needs for a kitchen, it is crucial that these variables are defined as early as possible to ensure efficient and practical planning is done.

Some other questions that you should be asking yourself are as follows;

- Do you plan on expanding your menu options in the near future?

- How often will your menu require full stock rotation?

- What is the ratio of dry and fresh produce, and how much space will you need allocated for both of these?

It’s no fun getting 5 years down the track and realising that certain upgrades are needed due to ineffective design and appliance selections. The correct setup for your business is always about striking the best balance and compromise – for now and the future.

We recommend consulting with a professional regarding these future plans as early as possible, so you can get the best efficiency for your dollar from your business. For further information, we have collated the relevant products below that were used when drawing these comparisons.